PCLGold Leads Pipe Stress Evaluation with ASME Code Changes with Shell FEA in Latest Software Release

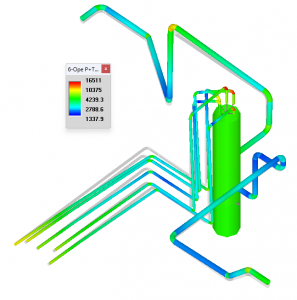

PCLGold now includes 2024 ASME B31.3 and B31.1 updates, reinforcing code compliance and FEA-based pipe stress analysis with shell models.

PCLGold integrates directly with existing beam-based piping designs, applying FEA at intersections, nozzles, and other areas of geometric or mechanical complexity. This targeted approach supports more informed decisions during design, analysis, and verification, especially in systems where the typical B31 assumptions may not be valid.

The software helps reveal localized stress behavior in scenarios such as:

- Friction reversal at supports during thermal expansion and shutdown

- Axial and torsional effects on branch connections

- Load shifts in overhangs and risers due to condensate or sag

- Structural response changes caused by pressure or thermal stiffening

The inclusion of 2024 ASME B31.1 and B31.3 updates ensures current code alignment while maintaining PCLGold’s broader objective: to improve stress prediction fidelity in critical piping systems.

PCLGold’s analysis framework is supported by real-world validation, including fatigue, burst, and acoustic testing performed by Paulin Research Group. This foundation helps engineers assess conditions that influence fatigue life, equipment loading, and system reliability.

About Paulin Research Group

Paulin Research Group (PRG) develops advanced engineering software for the design and analysis of pressure vessels and piping systems, focusing closely on finite element analysis (FEA) and compliance with recognized industry codes. The PRG product portfolio includes PCLGold, PVPTPro, NozzlePro, FEPipe, Konnect, and others—each designed to address specialized requirements in FEA-based modeling. In addition to software, PRG offers consulting services led by experts in pressure vessel and piping analysis.

For more information, visit: www.paulin.com

Jordyn Hayden

CEI

email us here

Visit us on social media:

LinkedIn

Distribution channels: Chemical Industry, Companies, Energy Industry, Food & Beverage Industry, Technology

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release