Paulin Research Group Redefines Nozzle Analysis with Advanced Finite Element Analysis (FEA)

Paulin Research Group advances nozzle FEA with precision tools that go beyond WRC methods. New software release coming in March 2025.

Accurately evaluating nozzle loads is critical to ensuring the structural integrity of pressure vessels and piping systems. PRG’s solutions address these challenges head-on with features that enable engineers to analyze even the most complex nozzle configurations and loading scenarios with efficiency and precision.

Why Choose PRG for Nozzle Analysis?

- Linear and Nonlinear Analysis: Precisely evaluate material behavior under real-world conditions, from elastic deformation to plastic collapse, ensuring comprehensive design validation.

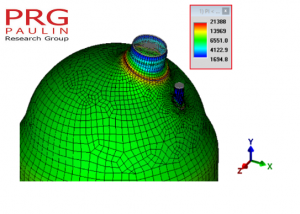

- Advanced Meshing Options: Combine structured meshing for uniform geometries and unstructured meshing with localized refinement to capture critical stress concentrations at nozzle-shell intersections.

- Comprehensive Modeling: Analyze nozzles on flat, hemispherical, torispherical, elliptical, cylindrical, and conical hosts. Handle configurations such as oblique, hillside, or clustered nozzles that surpass the capabilities of traditional methods.

- ASME Part 5 Compliance: Simplify stress linearization and ensure designs meet stringent ASME Section VIII Division 2 requirements.

Since 1990, PRG has been at the forefront of advancing FEA technology for pressure vessels and piping systems. For over three decades, engineers have relied on PRG’s tools to improve their designs, ensuring safer and more reliable equipment while meeting rigorous industry standards.

To further simplify and streamline nozzle FEA workflows, PRG is gearing up for an exciting software release at the end of March. This update will introduce new features designed to save engineers valuable time and enhance their ability to evaluate nozzle loads with unparalleled precision.

"The PRG suite, including NozzlePRO, PVPTPro, and FEPipe, stands as the premier choice for high-end FEA and ASME BPV and piping code compliance—truly second to none," said Michael Clark, P.E., Head of Engineering.

"Our team continually raises the bar with regular feature updates. In our upcoming release, we’re introducing structural attachments in flat heads, supporting both standalone evaluations and combined analyses with other structures and nozzles. Additionally, we’re incorporating the latest B31.1 and B31.3 code updates alongside enhancements to our automated meshing algorithms, further advancing the industry standard."

For more information on Paulin Research Group’s FEA solutions or to stay updated on the upcoming software release in March of 2025, follow us on LinkedIn.

Jordyn Hayden

CEI

email us here

Visit us on social media:

LinkedIn

Distribution channels: Chemical Industry, Energy Industry, Food & Beverage Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release